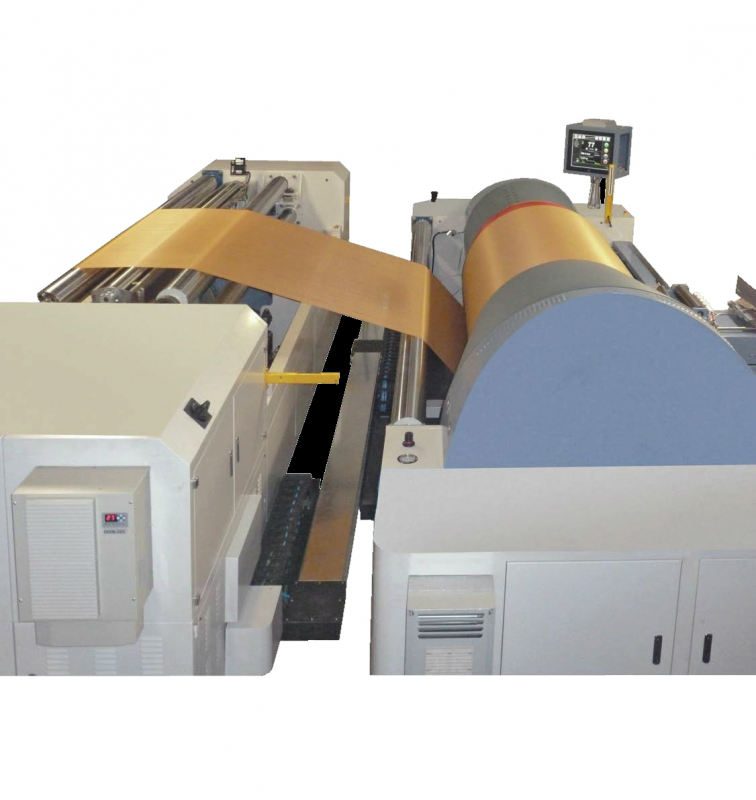

EUROTRONIC-1000-E2

order productOur Electronic Sectional Warper model EUROTRONIC-1000-E2 is designed to suite all present requirements of the most modern high speed weaving systems. High performance heavy duty fully computerized sectional warping machine.

Suitable for warping any natural or manmade yarns as well as their blends in all counts.

Having the following main characteristics:

TECHNICAL FEATURES:

Working width: up to 5.400 mm

Flange Diameter: up to 1.400 mm.

Sectional warping Speed: up to 1.000 Mt./min. (to be confirmed for yarns and tension required).

Beaming Speed: up to 220 Mt./min.

Standard section width: 40mm to 600mm

Necessary compressed air: 5 Bar @ 90 LPM

WARPING DRUM

Drum is made of lathed steel with 3.14m circumference, perfectly cylindrical and balanced.

The drum has 1.000 mm. diameter with fixed cone.

Angle on drum cone to be determined for type and thickness yarns to be warped.

BRAKES

Quick response disc brakes at both sides of the drum acting through a hydraulic circuit, stopping instantaneously the machine in case of yarn breakage.

SPEED VARIATOR

An electronic variator provides a constant pre-selected speed for both the warping and beaming process to keep a constant tension of the yarn. Speed controlled by PLC system.

WARPING MACHINE LATERAL MOTION

El urdidor está equipado con 4 ruedas que se deslizan sobre raíles. Dos de ellas son libres y las otras dos tienen movimiento positivo a través de un motor reductor.

WARPING CARRIER

Moved by means of a servomotor motor through an endless screw with a ratio from 0,001 to 8 mm.

Warping table initial and subsequent sections are made automatically and precisely positiones.

PRESSURE ROLLER ON WARPING TABLE

Warping table comes equipped with a pressure roller to give constant tension and pressure to the building yarn on drum. Section press roll is pneumatic and automatically controlled. Pressure is adjusted on touchscreen and controlled by PLC.

YARN BREKAGE MEMORY SYSTEM

Saves broken yarn information and stops machine automatically during beaming process.

LEASING REED

Threads coming from the creel are introduced in a leasing in a vertical leasing reed.

Provides a one touch leasing.

Pneumatic vertical reed movement.

Standard reed width 1150mm.

LBEAMING

The beam is driven an A/C motor of 45 KW.

This motor has an adjustable electronic speed device totally synchronized with the drum.

Beaming is equipped with automatic beam doffing utilizing a hydraulic cylinder to lease the beam to the ground.

The beaming speed is controlled through the PLC.

GENERAL CONTROL PANEL

Touch screen HMI control panel.

The warper is totally controlled through a touchscreen panel, controlling:

• Density of the yarn.

• Optimal number of sections.

• Width of each section.

• Stop the warper for pre-selected partial number of meter for crossing.

• Stop at the pre-selected number of meters.

• Speed traverse motion of the carrier and its positioning for each section.

• Maintain a constant lineal step less speed for beaming and weaving.

• Memory of yarn breakage during warping for beaming.

• All data on display.

• The traverse motion of the carrier can be pre-selected from 0,001 mm. up to 8 mm.

• Memory of all the definitive data for 999 warping and beaming for repetition.

OPTIONAL EQUIPMENTS

• IONIZING DEVICE

• PRESSURE ROLLERS AT BEAM

• OILING DEVICE